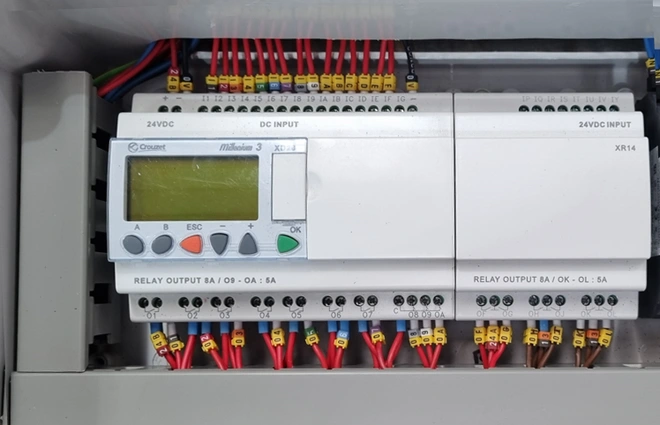

Standard Features

Diverter valve manifold pipe on the Buffer Tank is supplied for qty 3 delivery lines on all tanks as standard

Reliable industry leading milk pump

Compressed air regulator and Pressure Sensor included as standard to eliminate milk being dumped accidentally

3 supply line programme installed as standard with all tanks in the PLC

Pneumatic valve manifold block (in control panel) supplied as standard for up to 3 delivery lines

3 dosing pumps included as standard

Highlighted Features

Easy to install

Future proof allowing for further expansion

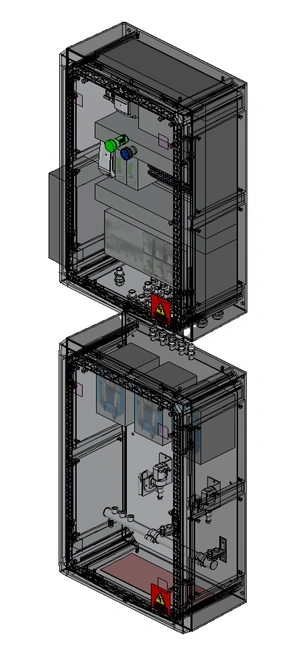

PLC displaying the current status and fault

Smart Layout for easy accessibility, maintenance, and troubleshooting

Improved and Adjustable liquid level

controllers to accommodate different

water characteristics with an updated

probe design to reduce the likelihood

of probes shorting out.Pump overload monitoring to raise

alarm if the milk pump is in fault and

the fault is displayed.

Alarms can easily be linked into

existing Autodialer if required.Alarms displayed on PLC screen and

status sent to Robot.

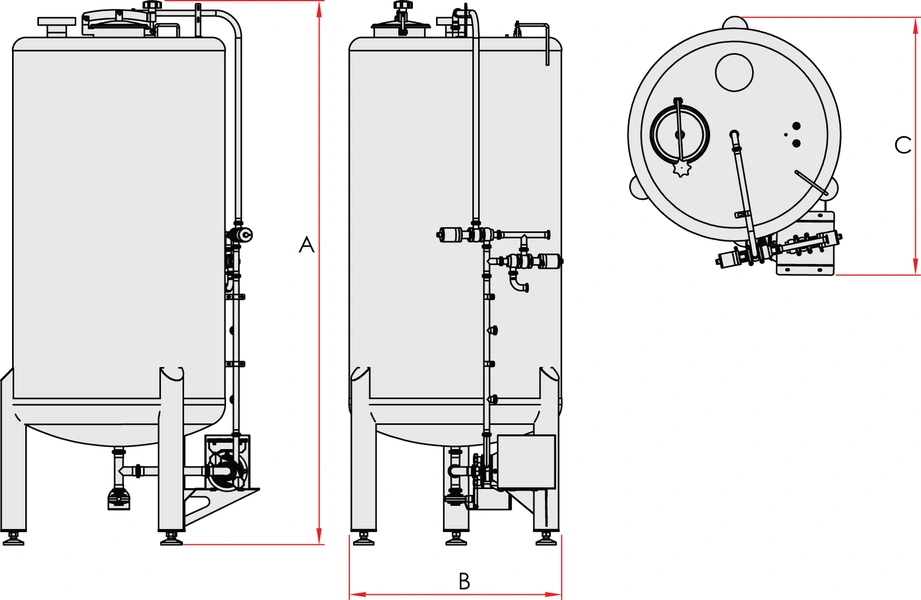

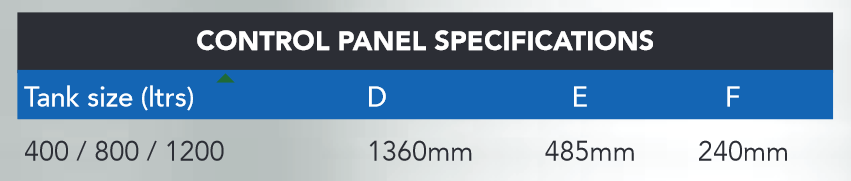

Details

All components used to regulate the cooling and washing functions are commercially available “off -the-shelf” parts if required readily available at affordable prices. Only reputable and well-known brands are used.

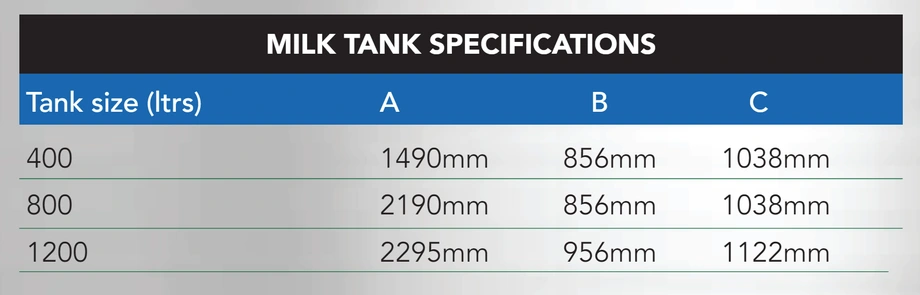

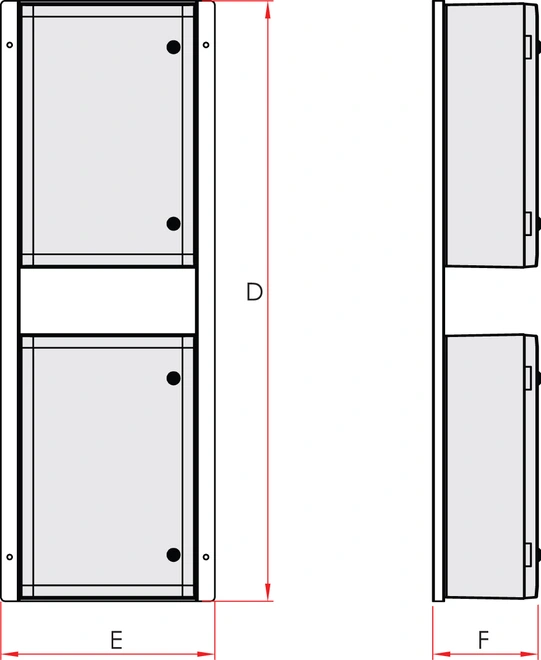

- Separate electronic and wet compartments on one wall mounting stainless steel backing plate

- Electrics and pneumatics in top panel.

- Dosing pumps, water solenoids and CIP manifold in bottom panel

- All devices contained within panel enclosures

You can download the brochure here

Certification

Here at Liscarroll Engineering, we are certified in Quality Management Systems in our designs and manufacturing of milk tanks and silos for the Irish and UK markets. You can see our certificate of registration here