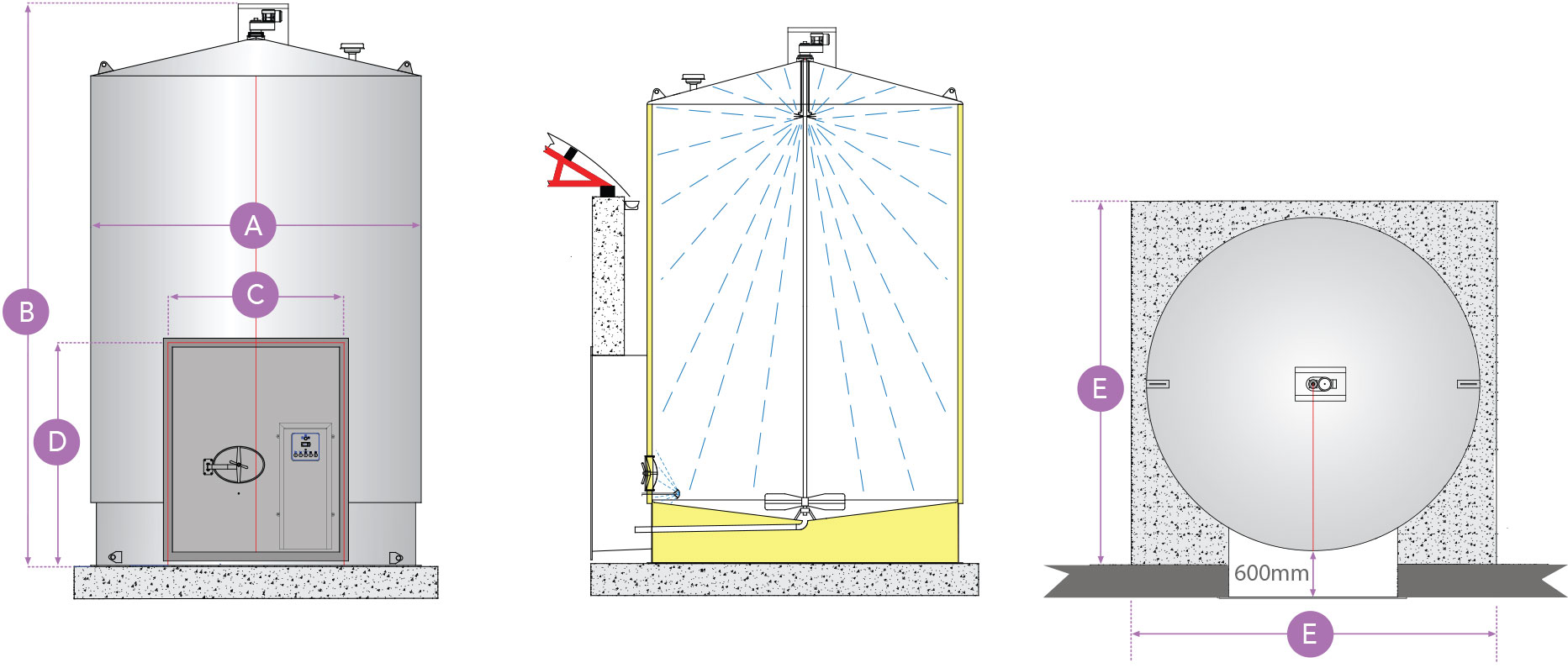

Milk Silos

At Liscarroll Engineering we understand the demand for high volume on-farm milk cooling and storage. Our high-quality Milk Silos provide the perfect solution where it is often impossible and uneconomical to extend the existing premises or to build new premises to accommodate conventional milk tanks.

Standard Features

Base and Side Cooling Evaporators

Conical Base

Hygienic milk-sampling system

Stainless Steel Alcove installed through wall to Dairy incorporating:

Wash & cooling Controls

Botom Access Manway

Non-Return Valve for bottom filling

CIP milk line connection

High Density Insulation

Stainless Steel access ladder with safety cage

Self-cleaning all Stainless Steel exterior

Available in Ice Bank and Direct Expansion

Highlighted Features

Maximum Storage with Minimum Space

- Customisable cooling plate configuration

- All stainless steel outer shell

- Flexible options for cabinets, valve work, ladders and refrigeration

General Silo information

Liscarroll Milk Tanks are designed to be reliable easy to use and service friendly.

All components used to regulate the cooling and washing functions are commercially available “off -the-shelf” parts if required readily available at affordable prices. Only reputable and well-known brands are used.

Option

- Independent Tank Monitoring & Management System

- Alerts via SMS, Email and Phone Call

- Daily Temperature Reports

- Remote Access Anytime Anywhere

- And Much More

Cooling Regulation

- Conventional thermostatic expansion valves to control refrigerate flow and protect the compressor. Located on the rear of tank on top

- Compressors(s) on DX tank with “pump-down” system to protect evaporator plates from possible damage from hot washing

- High Density Polyutherane (ECO friendly)foamed insulation up to 200mm thick between inner and outer vessels creating high rigidity and excellent insulation

- Minimum heat loss and reduced running costs

Agitation

- Standard SIREM motors. Motors that are made specifically for Milk cooling tanks and are the most widely used make on Milk Tanks across Europe and beyond

- Motors are protected from damage by preventing contact with wash water either by use of Waterproof Gaskets or raised Agitator Mounting Plate

LE-Series Controllers Include

- LE-200

- Built in Quick Wash and deep cool functions

- Option of automatic or manual descale

- Temperature and wash cycle step display

- Built in back-up cooling function

- Pre-configured one touch wash programmes and times for ease of use

- Flexible and future proofed solution

- LE-300

- Robot compatible with pulse cooling feature

- Complete monitoring capability

- Built in back-up cooling function

- Pre-configured one touch wash programmes and times for ease of use

- Built in Quick Wash and deep cool functions

- Option of automatic or manual descale

- Flexible and future proofed solution

Stand Out Features:

- Optimum Perforamnce

- Maximum Reliability

- Minimum Operating Costs

Our standard controller is the LE-200. This controls the cooling, agitation and washing functions

- Cooling start delay for the first milking

- Deep cool timed facility (temperature controlled at 20C) to ensure milk is at the required collection temperature sooner and to maximize use of lower rate electricity

- Optional visual or audible alarms (e.g. Cooling time exceeded for first milking)

Independent backup cooling controller (Carel) built-in as standard further protecting your investment.

OPTION: Our LE-300 controller in addition to the above has full Robot Milking compatibility and complete monitoring capability.

Cooling Units

- Copeland Scroll Compressors for unbeatable efficiency and reliability

Evaporator Plates

- Conventional thermostatic expansion valves to control refrigerate flow and protect the compressor. Located on the rear of tank on top

- Compressors(s) on DX tank with “pump-down” system to protect evaporator plates from possible damage from hot washing

- Superior energy efficient performance due to low volume evaporator plates resulting in less power required to fill the plates with coolant

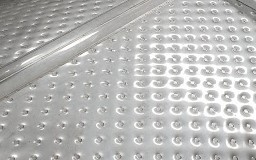

- Optimised dimple pattern in the lasered plates ensures high turbulence and more economical cooling

Certification

Here at Liscarroll Engineering, we are certified in Quality Management Systems in our designs and manufacturing of milk tanks and silos for the Irish and UK markets. You can see our certificate of registration here